And if you want guidance to manufacture your custom made aluminum component, please attain out to discuss your undertaking.

In 1808, English chemist Humphry Davy theorized that aluminum may be produced by electrolytically minimizing alumina or aluminum oxide, but lacked the required products to check his notion. It was not until eventually 1825 when Hans Christian Oersted developed an aluminum alloy according to Davy's ideas.

Our business practical experience and deep idea of manufacturing processes make sure aluminum sections are created to buyers’ certain demands. Few that with our wide producing community and you may rest assured that your aluminum parts will fulfill both of those your agenda and the very best criteria of good quality.

Extrusions—forcing a piece of aluminum by means of or all over a die, triggering the aluminum to conform on the die’s form and measurement.

Mining commences While using the removing of trees and vegetation. The topsoil is then eliminated and stored for that post-mining restoration system. In most forested areas exactly where bauxite mining normally takes location, the land returns to its primary ecosystem.

We're tests the Adhesion of Coatings and Plates. A lovely and durable complete can also be strong. We validate bond toughness by way of peel and cross-Slash tests.

The aluminum fabrication procedure involves careful and meticulous intending to guarantee merchandise are created to precise shopper technical specs without having delays. At Xometry, our initial step should be to review the consumer’s structure and determine the best producing strategies and system movement to the challenge.

Warmth Procedure Processes: aluminum fabricators use these processes to improve the toughness and durability of rods. They will then withstand their intended programs.

Knowledge the variations involving various grades and alloys is important in aluminum fabrications. Aluminum is not all made equivalent. Each and every alloy and aluminum excellent has distinctive features which make them suitable for different programs.

The melting position of aluminum is reduced, and its thermal conductivity is higher than metal’s. It may be difficult to weld the metallic with no leading to distortion or melt away-by.

We use electronic producing systems along with our chopping-edge machining products to just take your challenge from the ideation phase to completion.

That’s why it’s critical to familiarize by yourself with the precise procedures associated with aluminum fabrication Before you begin experimenting.

Comprehension the constraints of aluminum metal aluminum fabricators will allow us to generate far better decisions and improve our processes to lower these troubles.

Also, when feeding aluminum welding wire during the welding method, it may become simply tangled. This is because of The reality that aluminum wire is softer than metal and here so has diminished column toughness.

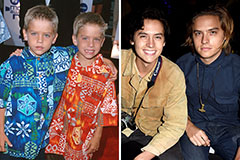

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!